FDM Multicolor optimisation and how to save print time as a designer

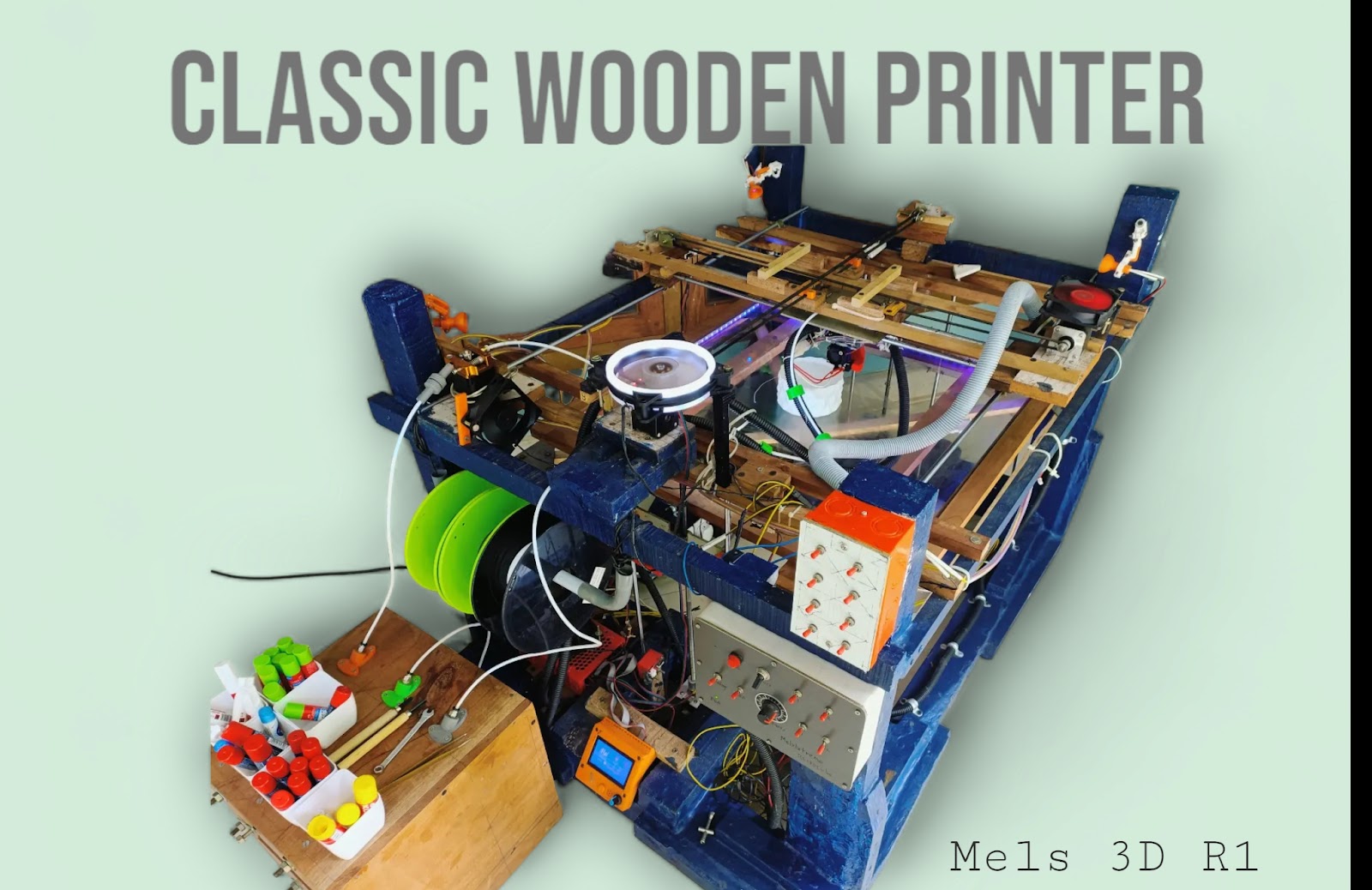

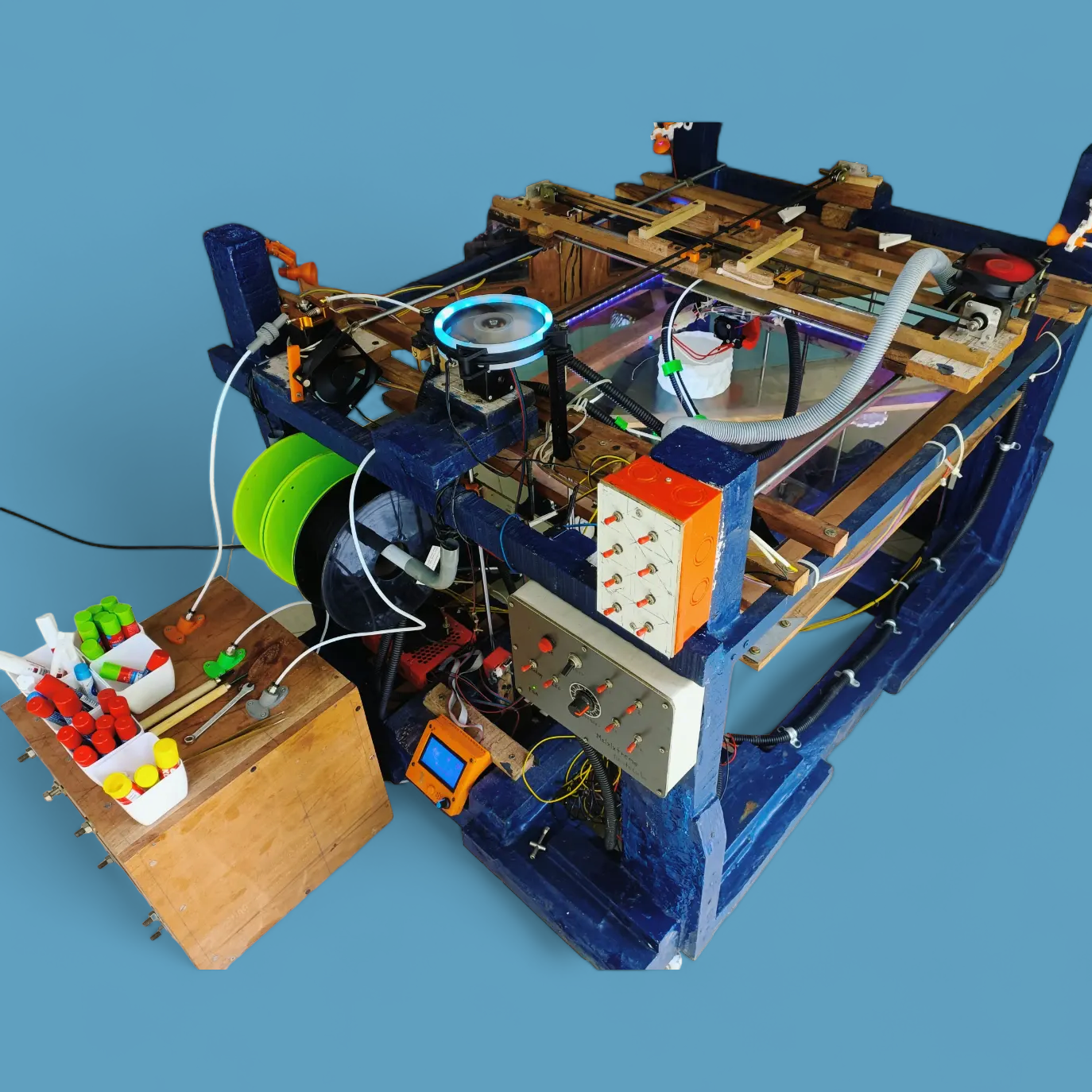

The project began with the development of a 1-meter Cartesian Cube prototype machine. However, to facilitate easier transportation around the house, the printer's width was reduced from 1 meter to 83 cm. Making it a rectangular frame and cubical print bed. This naming it as R1. This modification retains the essential functionality of the original design while making it more convenient for home use.

Build Specs

Max tested printing speed : 150mm/s

Best results as of now : 75mm/s with 550 acceleration & 0.04 junction Deviation

Printer dimensions :

Length : 120 cm

Width : 83 cm

Height : 83 cm

Current Print Dimension :

60 × 60 × 50 cm

Print Dimension upgradable :

120*83*83 cm

Endstops set to : 48x * 38y * 28z cm

Firmware :

Marlin 2.0.6.1 upgraded to 2.0.8.2 with SKR2

Steps per unit

A4988 (100, 100, 2600, 95)

DRV8825 (200, 200, 5200, 190)

Iinear Advancement K = 0.22

Baud 250000

# printing Material (All metal)

[PLA, ABS, Nylon, ASA, TPU etc]

# 1.75mm filament

# 100k ntc b 3950 Thermistor

# 12v 40w heating cartridge

# E3D V6 All Metal J-Head Hotend Extruder

PID Tuning

195°c

Kp : 41.88

Ki : 7.41

Kd : 59.18

185°c

Kp : 42.65

Ki : 7.23

Kd : 62.90

# Fat Nema extreme Extrusion stepper

# 5mm glass Bed

# Heavy wooden framework for vibration absorption.

# 0.4mm nozzle (0.2-2mm range)

# print cooling fan + Motherboard cooling

# RGB Printing Lights

# Arduino Mega R3 2560 upgraded to SKR2

# A4988 Driver upgradable to TMC

# 12v 20A power supply

# Isolated power supply for LED and Ramps Cooling

# Full Graphic Display

# 8mm SS rod with steel LM8UU

# PTFE tube with Bowden Extrusion

# Smooth wheels for printer transportation

# LED spot light for print Highlights

# 1 meter PTFE tubing (upgradable to y filament splitter)

START GCODE

G21 ; Millimeter units

G90 ; Absolute XYZ

G28 ; Home all axes

G1 Z5 F100 ; Z raise

M109 S240 ; Wait for nozzle temp

G92 E0 ; Reset extruder distance

G1 F2000 E10

M106 P0 S20

M117 Melxlxtreme Active

G1 X140 Y170 E5 F1550 ; move to start

G1 Z-0.19 F1200 ; Move to layer height

END GCODE

G91 ; Relative position

G1 E-12 F1300 ; Retract 12mm at 1300mm speed

G0 Z4 F2000 ; fast move z +4

M104 S0 ; Turn off nozzle heater

G90 ; Absolute Position

G28Y ; Home Y

M84 ; Disable steppers

M300 P250 S262

M300 P25 S0

M300 P250 S330

M300 P172 S0

M300 P184 S311

M300 P250 S415

M300 P180 S0

M300 P256 S233

M300 P250 S349

M300 P184 S0

M300 P250 S262

Test Prints

Comments

Post a Comment