FDM Multicolor optimisation and how to save print time as a designer

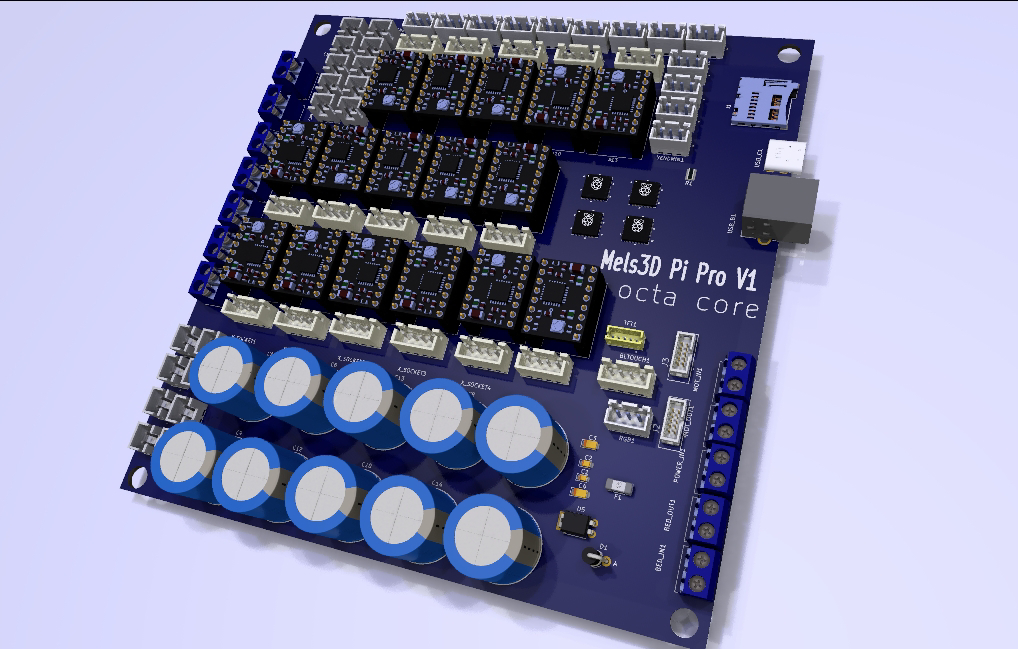

Mels3D Pi Pro V1.0 is an Octa-Core 3D printer Motherboard based on Raspberry Pi 2040. The RP2040 is a 32-bit dual ARM Cortex-M0+

As of now, Mels3D pi pro is the first ever octa core 3d printer motherboard ever being developed.

The motherboard is capable of running 16 Steppers which pushes the limit of whats possible. The Pi pro V1 Is being developed to integrate Mels3D Color Madness, A 7 color mixing Extruder which needs 7 Extruder steppers, which no other 3D Printer motherboard can handle alone.

Started as a fun project, It got some potential and as an audio engineer, we love the filter caps, can be used as a mini power backup.

Features :

16 Stepper support

Power supply filter and UPS

Additional GPIO pins for expansion and Development

Features in Developmental stage :

A Standalone motherboard that can run Marlin without the need for an additional raspberry Pi.

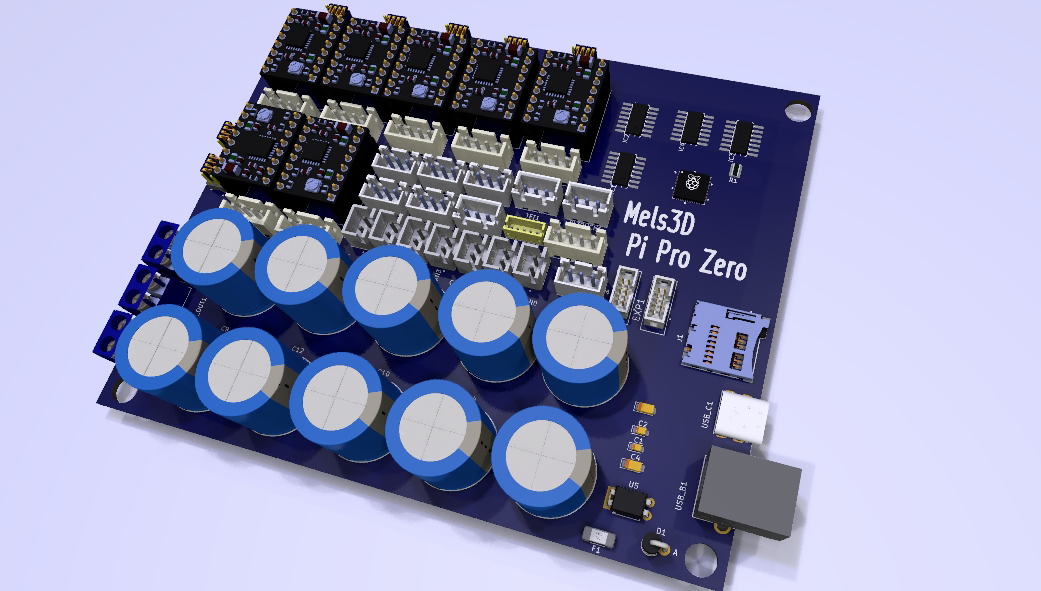

PI PRO ZERO

Pi Pro Zero is the created for making the development of Pi Pro V1 simpler and cheaper as Marlin Hal coding is complex with more peripheral pins. The solution was creating a standard board where the additional features can be worked on.

PROJECT RESOURCES

Mels3D Pi Pro in GitHub

https://github.com/MELS3D/Pi-Pro

Stable Marlin experimental

https://github.com/MELS3D/Marlin

Comments

Post a Comment