FDM Multicolor optimisation and how to save print time as a designer

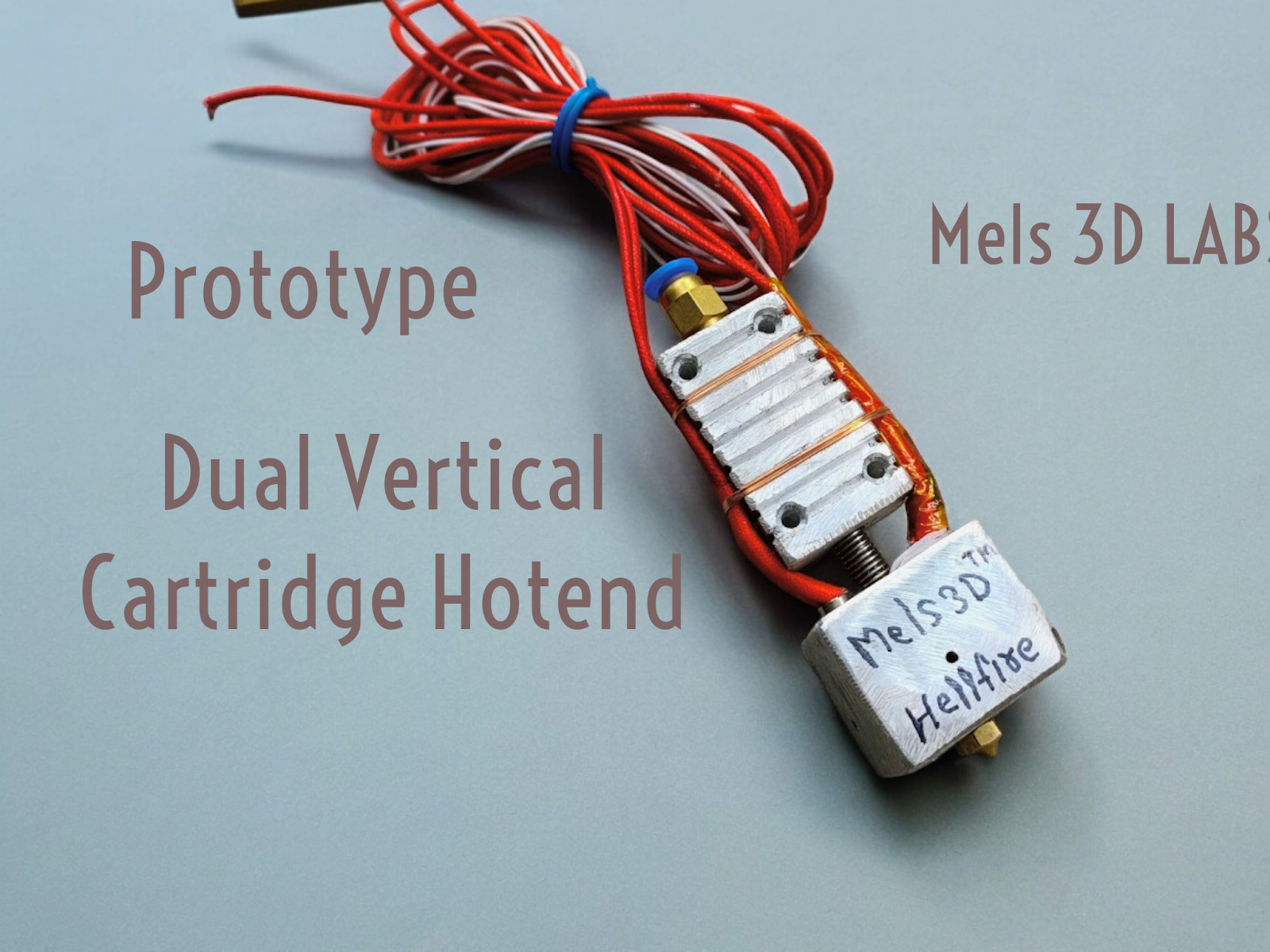

Before making fun of my marker on the Heatblock, I was lazy Doing CNC branding. It was just for a demo pic.

Hellfire is named after the thought whether the not the heatblock will wreck hellfire.

The concept behind is simple, that is heating the filament equally from both sides vertically while traditionally the heater catridge are placed horizontally.

Hence achieving fast and constant filament melting and increased printing speed.

CONFIGURATION

It is wired paralled to existing heater port.

The feature can be enabled in marlin by

// control heater 0 and 1 in parallel.

//define HEATERS_PARALLEL

In config_adv

#if ENABLED (HEATERS_PARALLEL)

#DEFINE WRITE_HEATER_0(V)

{ WRITE_HEATER_0P(V); WRITE_HEATER_1(V); }

#ELSE

#DEFINE WRITE_HEATER_0_(V)

WRITE_HEATER_0P(V)

#ENDIF

Comments

Post a Comment