FDM Multicolor optimisation and how to save print time as a designer

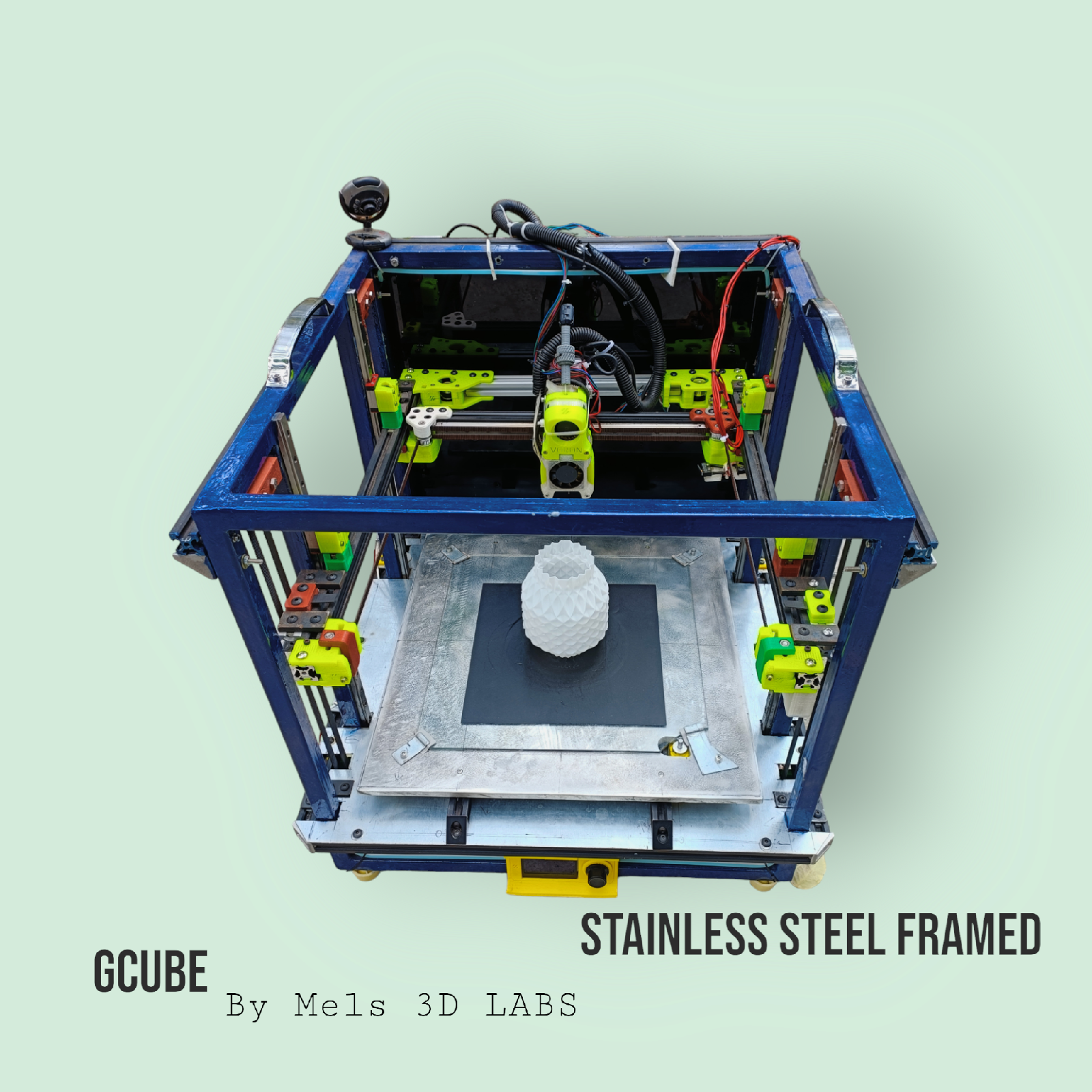

GCUBE The superior print quality prototype by Mels3D LABS.

Key features:

# Welded Steel frame for extra stability.

#12mm Industrial linear rail.

# Slim MGN 12C Gantry block.

# Gantry divided Z belt & Z rail placement for extra Z stability.

#Aluminum + Glass bed.

# Rebarred Z belt clips and Z pulleys with adjustable position.

#2300mm/s tested print speed on Hellfire with 80k accl.

#Raspberry pi + Octopus powered klipper.

HISTORY

The GCube is the latest Mels3D Design using a Core XY with a 32 bit Motherboard and Voron Extruder.

Using 12MM Linear Rails for extra stability and to achieve low maintenance, fast and consistent printing speeds and to battle ghosting, Zbanding and moisture related issues.

The name GCube is derived from the calibration cube printed by R1. The print was flawless, where Mel named it The God Cub, hence the name was reserved for the next plastic printer, whatever it is, As cube was superior to all the prints ever made. Adapting the name from the cube, Mels wanted to achieve same perfection.Using what is available until a permanent design has been made. Hence borrowing some voron 2.4 parts which are 3d printed.

Print Quality

Comments

Post a Comment