FDM Multicolor optimisation and how to save print time as a designer

The idea was sparked as i was walking to the town, where i notice thrown away LED Bulbs polluting the grasslands.

Later that day, Mels3D modified V020A2 Table lamp and made it into a prototype Bulb. The casing, Body is 3D printed with eco-friendle biodegradable PLA.

RECYCLABILITY

The major disadvantage of the LED lights available in the market is that once it fails, its impossible to repair. Companies seal the body with strong adhesives and mount the PCB in a way that it cant be taken out without ripping off the wires. Hence the customers are forced to buy new. From a eco-friendly prespective, over time it creates a lot of E-Waste.

An average household has about 10 LED, in which personally we had to replace or buy new 3 of them in the last 6 months. Over time the brightness of LED reduces, only if there was a way to replace those LEDs.

The Bulbs we made consists of LED modules which can be replaced easily, solving the major problems mentioned above.

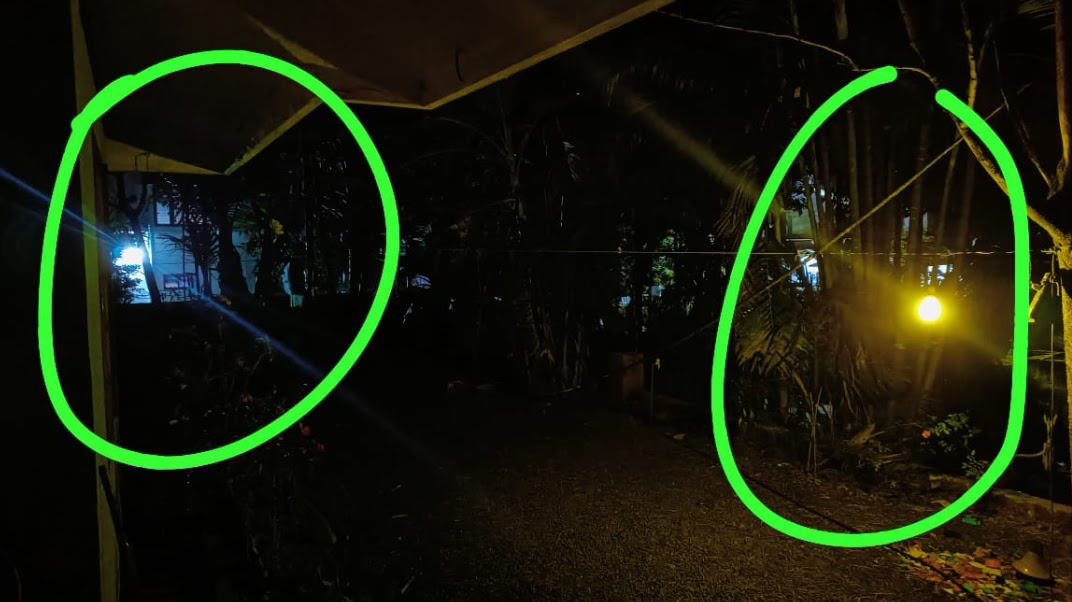

LIGHT COMPARISON

The color of the 3D print determines the color of the Light emitted. As it was a prototype, The yellow PLA used shows average readability showing promising signs for testing it with White and transparent PLA Filaments.

TYPICAL LED VS MELS3D LED-BULBS

Here's the side by side comparison with a traditional cool white 10W LED Bulb with the 10W Bio-Bulb we have. Both are almost similar except the white is a bit brighter, Hence a transparent or white PLA would make it a fare comparison.

Even if the 3D printed LED BULBS wouldn't cut it for a home lighting replacement, it would make the best fancy-party show bulbs. We spend a lot for decorations which we throw away next time. Those E-waste do pollute nature over time. A 3D Printed Bio-Bulb is significantly expensive, But the servicability, eco-friendly design would make small changes over time if accepted widely.

Table lamps and Lanterns

Comments

Post a Comment